iPLAS enables real-time data acquisition

from all processes

and sources.

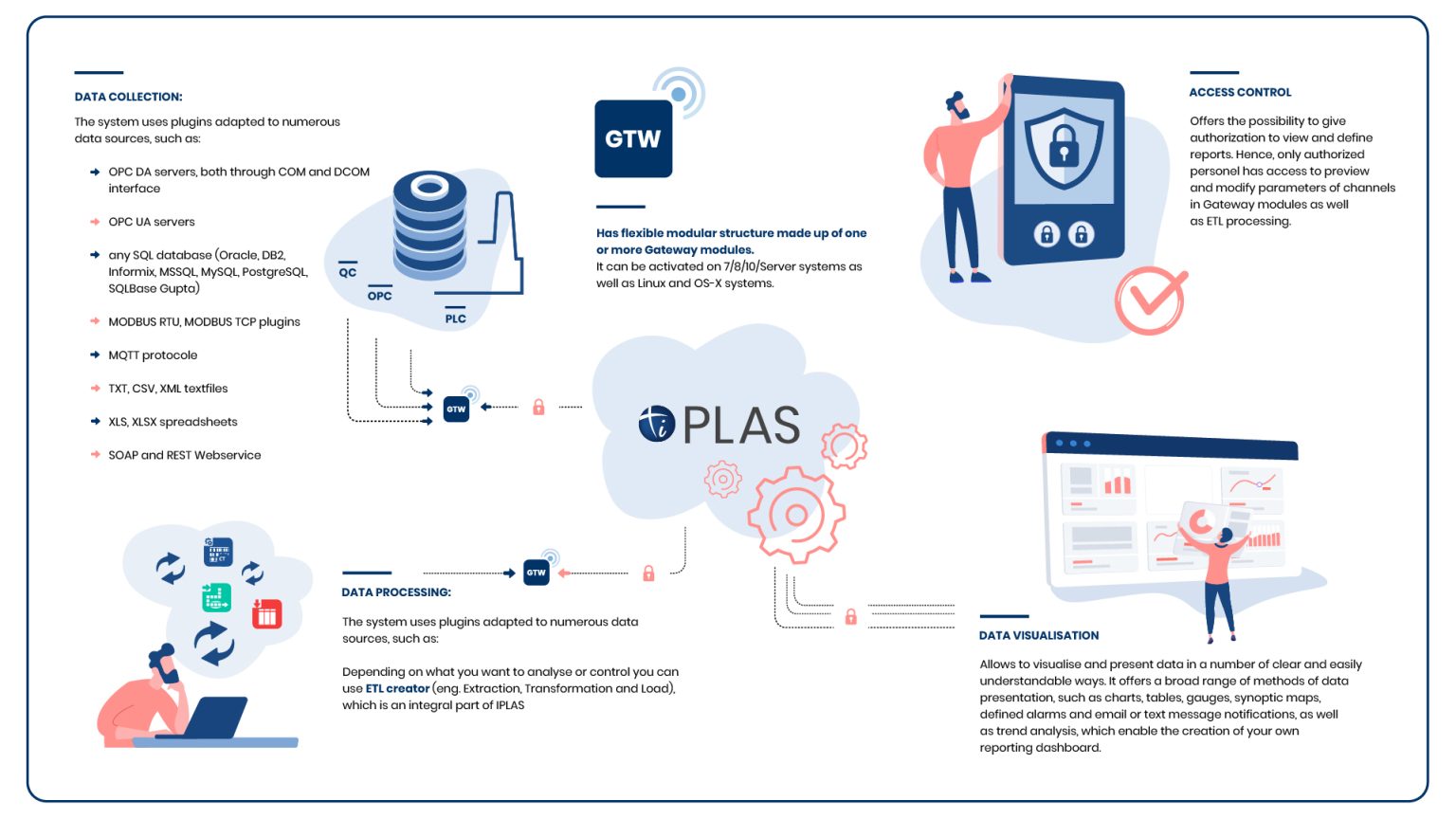

- We gather data from machines, automated processes, and manual processes (external panels, QR codes, RFID codes), allowing you to aggregate data in one place.

- If you have multiple factories, we integrate the data so you can have a comprehensive view and visualization of the data in one environment.

- We securely store data in the cloud or on your server, adapting to the needs and procedures of your organization.

- We know how to efficiently utilize data through data processing (ETL process) - we combine different data, you analyze and visualize them in any graphical form, and display them in your chosen location within your organization.

WHAT IS iPLAS

FAST IMPLEMENTATION AND INITIAL RESULTS VISIBLE ALMOST IMMEDIATELY

iPLAS Platform - system environment with a tailored reporting dashboard

for every level

of your company.

- iPLAS allows visualizing and presenting data in a clear and understandable way for every level of your organization,

- you choose the data needed for analysis and decide on how to present them (chart, gauge, Gantt chart, synoptic map, table),

- you can quickly create flexible reporting dashboards tailored to your needs.

WHAT IS iPLAS

HOW DOES iPLAS WORK

FAQs

LEARN MORE ABOUT iPLAS

Communication between iPLAS and other systems (e.g., ERP) can occur through text files generated by iPLAS-connected systems (e.g., CSV format), or by enabling direct data retrieval from the connected system’s database. Both approaches are practiced within iPLAS implementations.

The iPLAS system employs TLS data encryption, meeting the highest applicable security standards—similar to those used in online banking. Additionally, to safeguard sensitive production information, we utilize X.509 certificates.

To accommodate your facility’s needs, we’ve designed two solutions: storing data in the cloud or within your infrastructure.